Stacey Bales and Sara Mortensen began working at Bales as young children. Explore the challenges and rewards of their path to leadership.

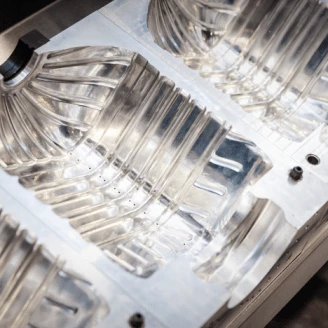

COATING ALUMINUM FOR PROTECTION

Join Harry Raimondi, the Technical Service Manager at Bales Metal Surface solutions, as he explains the importance of coating aluminum for protection. Harry has been in the mold making and surface solution industries for over 30 years.

Harry will explain how plating can be applied to aluminum molds for a variety of benefits including: protection, increased production, maintain thermal conductivity and improved part release.

This low temperature application can turn your prototype mold into a long lasting production mold. Plating is also a successful way to maintain the proper finish for consistent output.

FEATURED COATING: Electroless Nickel Plating

Lorem ipsum dolor sit amet, conse ctetur acing elit. Nam selg blandit est vehi cula mi viv erra, ac tem pus arcu pha retra. Aen ean eget nunc id mauris vulp utate luctus magar dellum toma. Lorem ipsum dolor sit amet, conse ctetur acing elit. Nam selg blandit est vehi cula mi viv erra.

Tricks of the Trade

Plating is a cost effective way to optimize the performance of aluminum molds by increasing the hardness.

We will discuss what types of aluminum are best for a polished finish, tips on how polished finishes along with coatings are used for maximum protection and part release and an inside look at masking techniques for the best result.

We will also share with you ways to communicate to your plating supplier in regards to timing and coordination for efficient job processing.