Achieve Your Ideal Surface Treatment

Secure Better Parts Performance with Bales

Demand for bolts, nuts, screws, and rivets is growing, positioning the global fastener market for 4.1% growth from 2021 to 2028. But supply chain disruptions and more calls for custom solutions are slowing down manufacturers.*

You can improve productivity by choosing the right metal finishing solution—and Bales can help. We fuse science and craftsmanship to deliver exceptional results for fastener manufacturers worldwide.

Since 1978, we’ve been protecting metal surfaces in ways others don’t dare. From bolts to buckles, your fastener components will benefit from our legacy of customer satisfaction, integrity, and innovation.

Fastener Solutions FAQs

Though small, fasteners play a critical role in various applications. Our specialized coatings ensure their peak performance. This FAQ explores the benefits of our solutions, enhancing the strength, corrosion resistance, and longevity of these essential components and highlighting the diverse applications we support.

If your fastener project is ready for a detailed quote, we invite you to visit our Request a Quote page to get started today.

Our dedicated FAQ page is the perfect place to go for additional information to help you make the right choice for your needs.

Solve Your Corrosion and Release Issues

Bales’ Electroless Nickel and proprietary NICKLON™ coatings protect against corrosion while achieving optimal lubricity and torque in fastener production applications. In most cases, barrel plating can be used for fast, cost-effective bulk processing. Where parts are too delicate or detailed, a standard rack plating is still an option.

Electroless Nickel

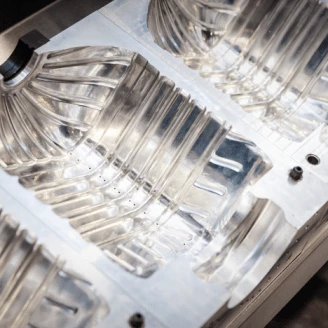

Bales’ exceptionally thin Electroless Nickel coating protects against corrosion and abrasion. This coating will plate evenly and into fine details like deep ribs.

- .003” > Plating Thickness

- 1.0 mil deposit, 1,000+ hours Corrosion Properties

- 45 Rockwell Hardness - HVN100

NICKLON™

Bales’ proprietary NICKLON™ coating combines Electroless Nickel with PTFE. It protects against wear and corrosion while providing superior lubricity and release.

- 45 Rockwell Hardness

- 0.10 Coefficient of Friction

- PTFE 8-9% Composition (WT)