MAXIMIZE YOUR STAINLESS STEEL PARTS LIFESPAN WITH PASSIVATION

Your stainless steel parts are prone to corrosion with regular machining. Maximize their resistance with Bales’ highly effective passivation services.

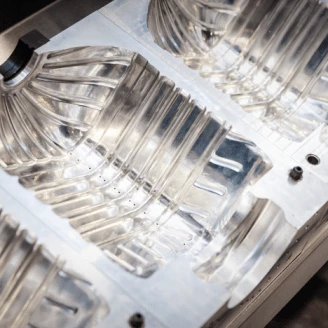

Our SS passivation process uses citric acid to dissolve the free iron and foreign particles that cause rust and oxidation, which creates a transparent oxide surface layer that’s highly resistant to mild corrosion.

Why Citric Acid?

Safety

Citric acid passivation is less hazardous than nitric acid passivation. It doesn’t require the use of mineral acids or sodium dichromate, which have safety and disposal issues.

Low Environmental Impact

Citric acid is an environmentally friendly substance. The Environmental Protection Agency and U.S. Food & Drug Administration classify citric acid with the “Generally Recognized as Safe” designation.

Greater Efficiency

Citric acid passivation cycles are typically shorter than nitric acid’s. That means faster parts processing and lower costs.

Why Citric Acid Passivation Is a Win-Win

When it comes to SS passivation, Bales’ citric acid solution is the winner. Maximize the corrosion resistance of your components while limiting the environmental impact with Bales’ stainless steel passivation services.