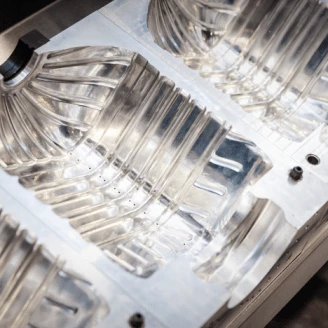

Expert Mold Polishing Services

Accurate mold polishing creates a uniform surface finish that will optimize part performance. Partner with Bales for mold polishing services that match your precise specifications. We’ll help you select the best finish for common and complex manufacturing issues:

- PART STICKING: Create easier release from the mold.

- PART RETENTION: Retain parts using blast finishes instead of undercuts and mechanical detents.

- IMPERFECTIONS AND INCONSISTENCIES: Remove tool and machining marks and hide imperfections.

Available Finishing Solutions

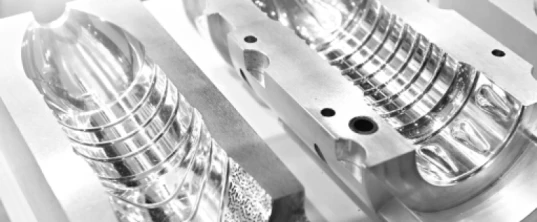

Diamond Finishes - Hard

Diamond polishing creates the finest finish for highly visible or lens-quality parts. The SPI* A-2 is the most widely used diamond finish, with excellent release and appearance. The SPI A-3 is ideal for release where a high-gloss appearance isn't required. All diamond finishes work well with chrome and nickel coatings.

*SPI® is a registered trademark of Plastics Industry Association (PLASTICS)

Paper Finishes - Semi

Paper finishes are the second most-refined option after diamond polishing. They produce a slightly reflective or glossy shine and a very good release. Choose paper finishes for products that don’t require a decorative or visual effect.

Stone Finishes - Low

Stone finishes are the most economical polishing option. They’re a good choice for strictly functional molded parts where aesthetics don’t matter. Stone finishes provide a good release and deliver very little gloss to the plastic part. They’re also the first step in the process of diamond and paper polishing.

Why Bales Is Your Go-To For Mold Polishing Services

Looking to maintain the details and sharp edges of your parts? Partner with the precision mold polishing experts at Bales.