DIAMOND E.N.™

DIAMOND E.N.™ — A POWERFUL NICKEL COATING

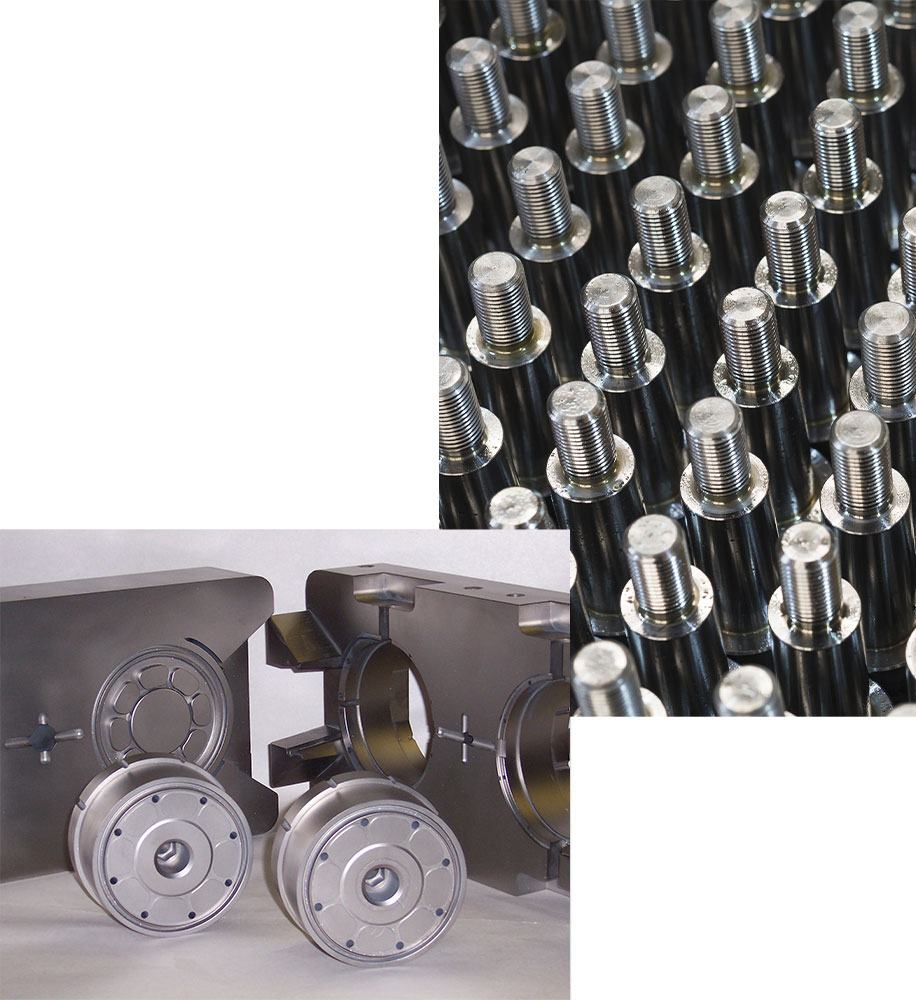

Diamond E.N.™ combines electroless nickel with diamond particles, making this diamond finish a solid alternative to hard chrome for saving on time and cost. Diamond E.N.™ has an exceptionally low coefficient of friction making it ideal for industrial manufacturing tasks that demand lubricity.

Experience the robustness of an electroless nickel coating with a 57 Rockwell hardness rating, which increases to 70 RC after a 550°F (288°C) heat treatment.

DIAMOND E.N.™ BENEFITS

The electroless nickel diamond coating isn't just about hardness. It ensures a longer lifespan for your parts and components, offering unmatched protection against wear and tear. This makes it a cost-effective and reliable choice for any industry requiring superior performance and longevity.

- 70 Rockwell hardness rating after 550°F (288°C) heat treatment.

- Easily stripped, leaving no damage to the base material.

- 3-6 Taber wear index (TWI).

LOW-FRICTION COATINGS

Do you have parts prone to getting rubbed the wrong way? Solve your abrasion and wear problems with our abrasion-resistant coatings.

ABRASION-RESISTANT COATINGS

Are release issues causing downtime in your shop? Reduce friction and achieve uniform treatment with our lubricity and release/low-friction coatings.

DIAMOND E.N.™ PLATING FAQS

Learn how Diamond E.N.™ enhances industrial component durability. Our FAQs explain the reasons why Diamond E.N.™ is an excellent choice for precision equipment, its advantages over ceramic coatings, and the sectors that benefit most from its exceptional hardness.

How Does Diamond E.N.™ Enhance the Durability of Industrial Components?

Diamond E.N.™ is an advanced coating that combines the hardness of diamond particles with the protective qualities of electroless nickel. It offers unparalleled wear resistance and extends the life of industrial tools and components.

What Makes Diamond E.N.™ a Superior Choice for Precision Equipment?

In What Ways is Diamond E.N.™ Superior to Ceramic and Other Coatings?

Unlike ceramic coatings, Diamond E.N.™ provides exceptional hardness and resistance to wear, making it ideal for applications that demand the highest level of durability and protection.

Which sectors benefit most from implementing Diamond E.N.™ coatings?

The aerospace, automotive, and medical manufacturing industries, known for their stringent requirements for durability and precision, find Diamond E.N.™ coating particularly beneficial, as it significantly enhances the performance and lifespan of their components.

0.10

COEFFICIENT OF FRICTION

57

ROCKWELL HARDNESS

185°F

applied TEMPERATURE

1000°F

MAX OPERATING TEMPERATURE

0.00005 to 0.0005”

Plating Thickness Range

4-6%

Phosphorus (wt)

8.1 g/cm3

Density

corrosion resistance rating

RELEASE RATING

ABRASION resistance rating

CASE STUDY: Diamond E.N.™ Achieves Higher Hardness

See the change that diamond finish brought to proprietary steel components made by one of Bales’ actual long-time customers.

Dennis Recker, Consulting Engineer at Lincoln Diagnostics