THE CHALLENGE

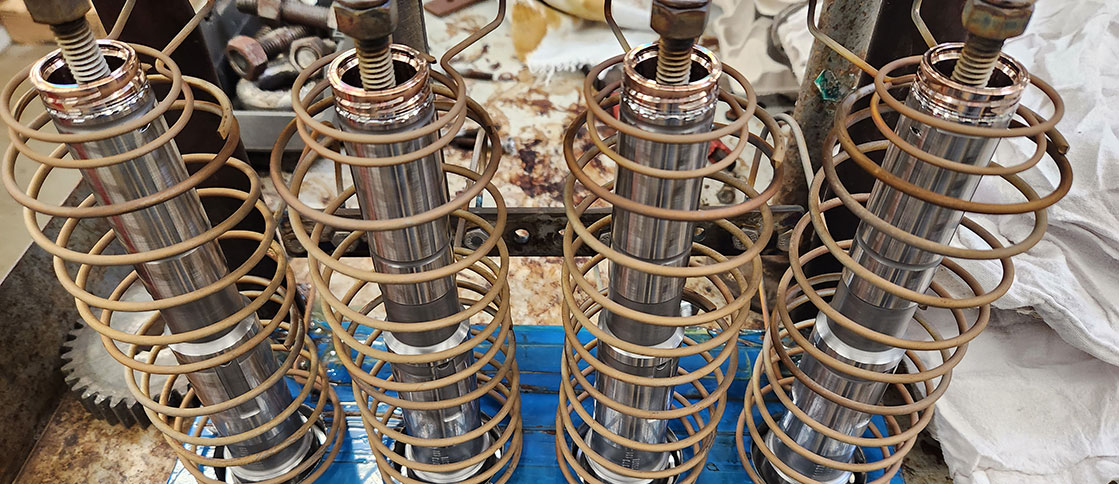

A leading injection molding manufacturer faced repeated failures due to galling in their carbon steel mold components. Galling, caused by excessive friction between moving parts, led to surface damage, material transfer, and even component seizure. High-wear areas like ejector pins, cores, and guide rails were particularly affected, causing several issues. Mold components wore out quickly, requiring frequent repairs and replacements, while surface damage on the mold often transferred to molded parts, leading to inconsistent product quality.

The company needed a solution to eliminate galling, extend the life of their molds, and maintain product consistency.

THE SOLUTION

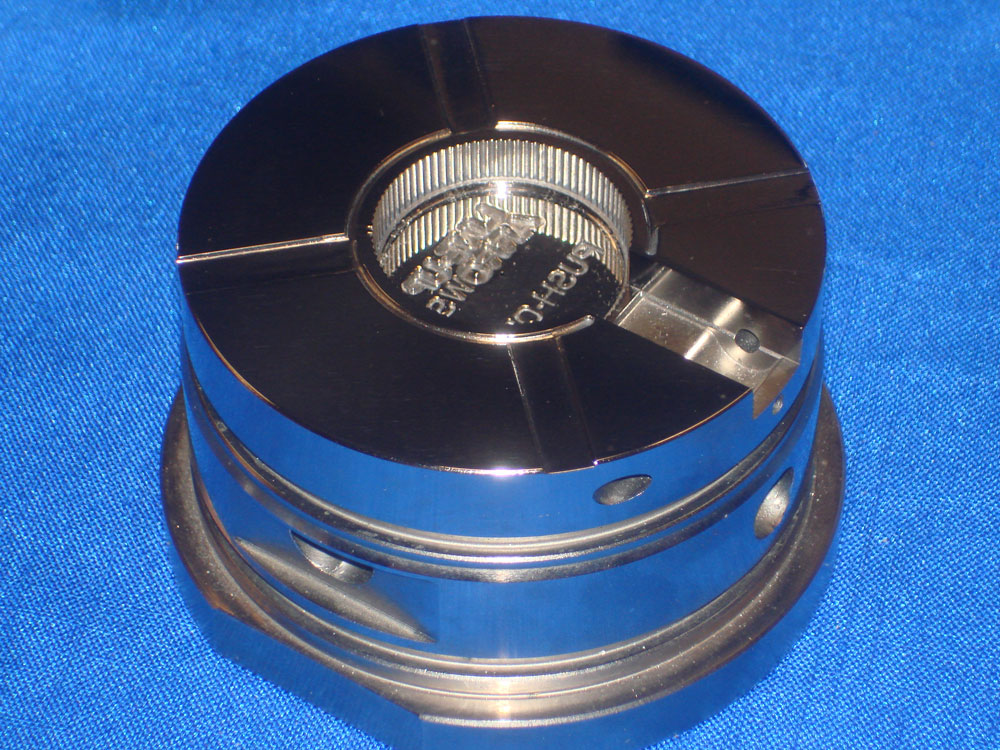

The team turned to Diamond Chrome plating, a composite coating combining the hardness of diamond particles with the durability of chrome. This advanced coating was selected for its exceptional ability to resist wear and minimize friction by bringing the surface hardness up to 85 Rockwell.. By applying the coating to high-contact mold components, the manufacturer aimed to address galling and improve overall mold performance.

The diamond chrome can be completely removed and reapplied when maintenance is needed. Maintenance plating is recommended after noticing signs of wear or performance changes.

THE RESULT

After implementing the Diamond Chrome coating, the results were immediate. The coated components showed minimal signs of wear, significantly extending their lifespan and reducing the need for repairs or replacements. Production cycles ran smoothly without interruptions from seizing or binding parts, and molded parts exhibited flawless finishes and consistent dimensions.

CONCLUSION

By adopting Diamond Chrome surface coating, the manufacturer resolved a persistent challenge, improving both mold performance and product quality. This case demonstrates how advanced surface coatings can provide practical and cost-effective solutions for the injection molding industry.

Investment: $1,350 for parts plating over five business days