MEDICAL

Since 1978, Bales has set the standard for innovation and reliability in metal surface protection, delivering finishing solutions which boost your productivity and ensure component reliability. Whether you manufacture vials, tubing or lab testing supplies, our team collaborates with you to provide precise, expert craftsmanship – ensuring your most challenging projects are completed on-time and within the exceptional tolerances demanded.

MEDICAL SOLUTIONS FAQS

Quality and safety are paramount in the medical field. Our coatings for medical applications, detailed in this FAQ section, meet the highest standards. Discover how our durable, biocompatible, and regulation-compliant coatings enhance medical devices and equipment.

How does Electroless Nickel benefit the industrial metal finishing processes?

Electroless Nickel is a proven choice in industrial metal finishing due to its remarkable corrosion resistance and durability. It maintains the surface finish of metal parts, preventing build-up and ensuring dimensional tolerance. With Bales’ Electroless Nickel coating, you achieve enhanced service life and improve the performance of critical components.

What are the key advantages of Nickel Boron coating in industrial metal finishing?

Nickel Boron coatings stand out in industrial metal finishing for their exceptional lubricity, superior release properties, and outstanding abrasion resistance. This coating plays a crucial role in optimizing the performance and longevity of metal components, making it a valuable asset in diverse industrial applications. Not all Nickel Boron coatings are created equal. With Bales’ proprietary NIBORE™ coating, you enhance function, improve manufacturing output, and defend assets from wear.

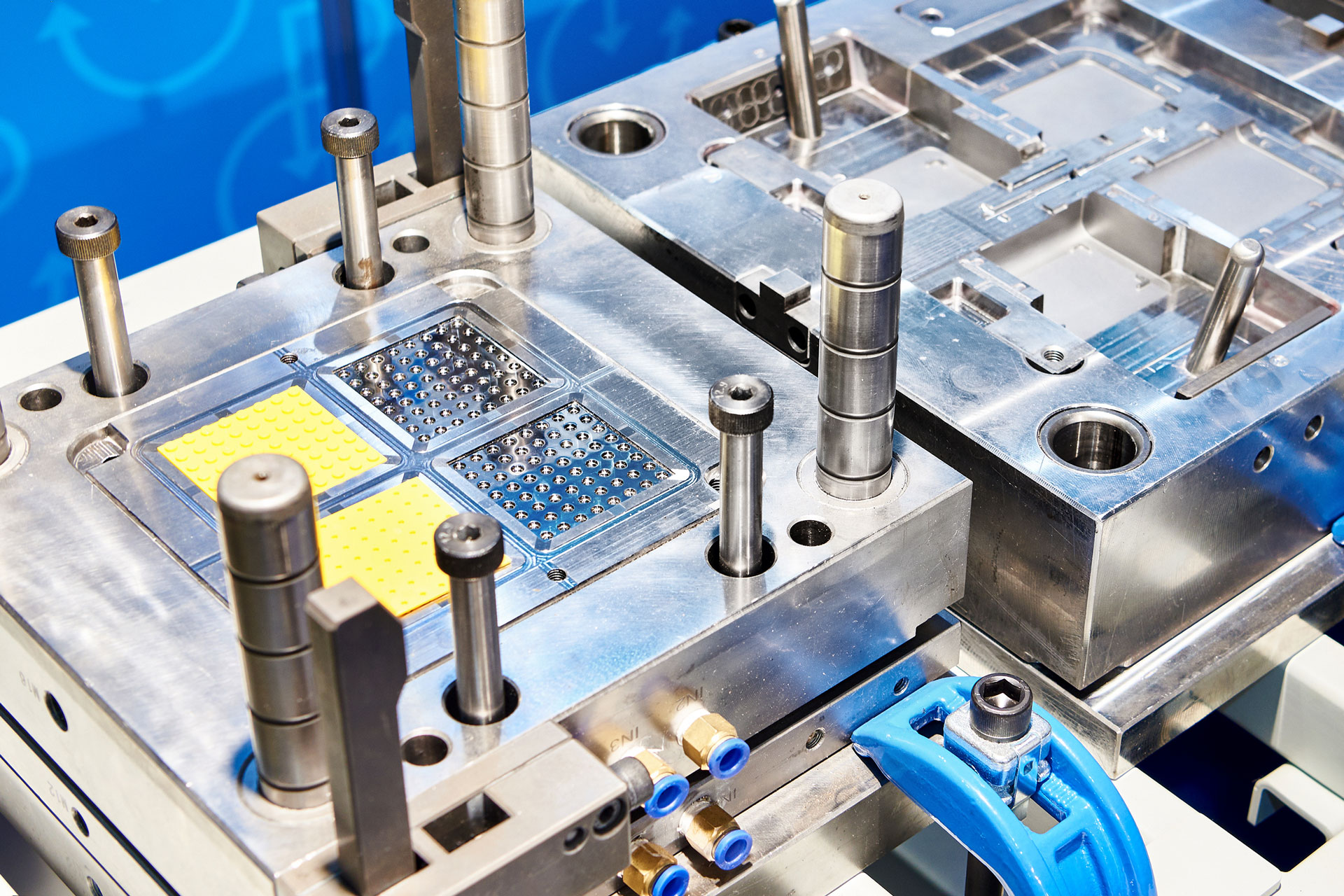

CASE STUDY: NIBORE™ Solves Leaching Problem

Beryllium copper lends itself well as a material for plastic injection molds. For that reason, MOS Plastics used beryllium copper for the mold microplates it designed and built for a medical device customer. However, a problem arose as the customer started production.

“They are extremely responsive to our needs, turning things around quickly, whether quotes or the placing process.”

Rob Zimmerman, Engineering Manager at MOS Plastics