A Powerful Nickel Coating

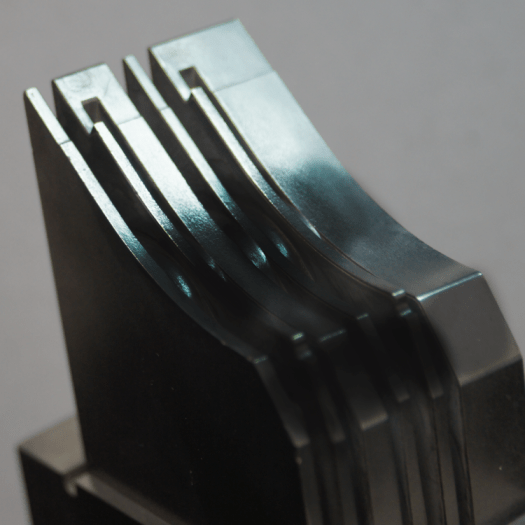

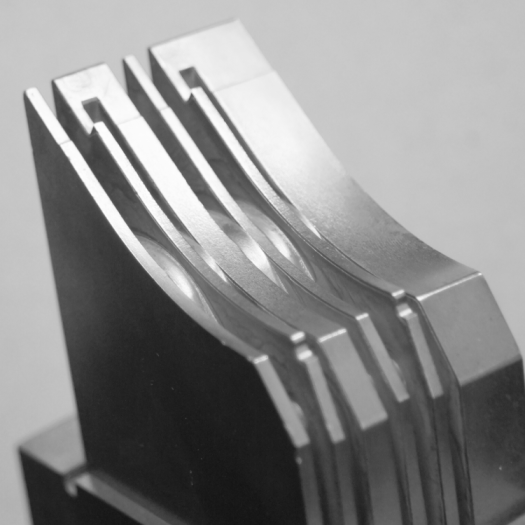

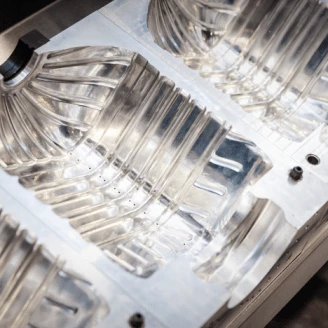

Diamond E.N.™ combines electroless nickel with diamond particles, making this diamond finish a solid alternative to hard chrome for saving on time and cost.

Experience the robustness of our coatings with a 57 Rockwell hardness rating, which intensifies to 70 RC after a 550°F (288°C) heat treatment. This elevated hardness level signifies our commitment to providing superior durability, ensuring your components withstand the most challenging environments.

Additional Diamond E.N.™ Benefits

What else can an electroless nickel diamond finish do for your parts and components?

The electroless nickel diamond coating isn't just about hardness. It ensures a longer lifespan for your parts and components, offering unmatched protection against wear and tear. This makes it a cost-effective and reliable choice for any industry requiring superior performance and longevity.

Why Diamond E.N.™ Is A New Standout

The nano-sized diamond particles in Diamond E.N.™ offer extreme abrasion resistance—and give chrome some tough competition. Use our Coating Comparison Tool to see how Diamond E.N.™ stacks up against other Bales coatings. Compare surface finishes and find the best solution for your needs.

A Real Diamond E.N.™ Success Story

See the change that diamond finish brought to proprietary steel components made by one of Bales’ actual long-time customers.

““Bales has done thousands of these parts for us and never lost one. I don’t know how they do it. I absolutely would recommend them.””

Read Case Study